Products We Serve

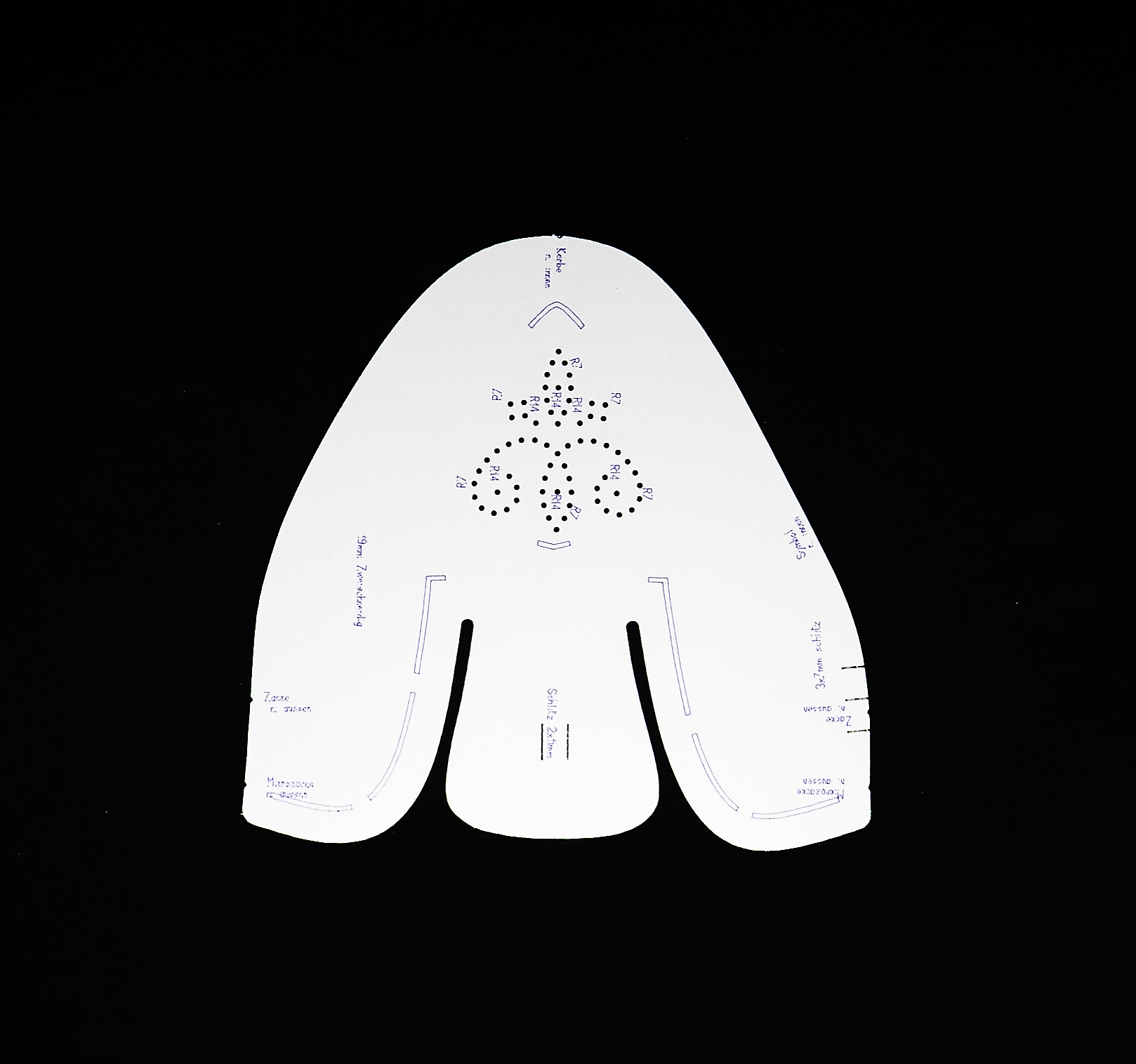

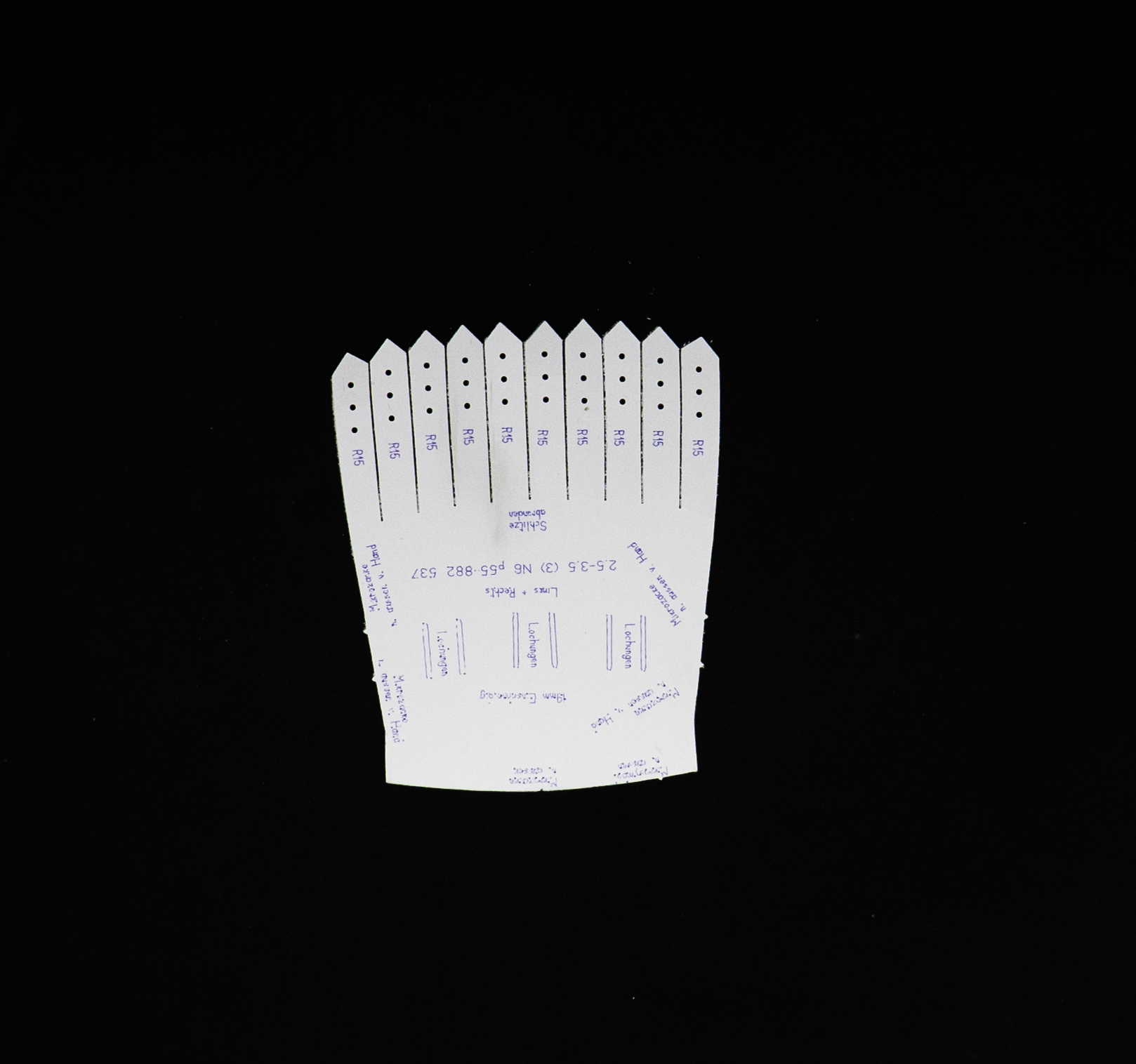

Clicking Dies

Clicking dies also known as steel-rule dies or cookie cutters are used for cutting leather as well as paper, cloth, fibre, felt and fabrics...

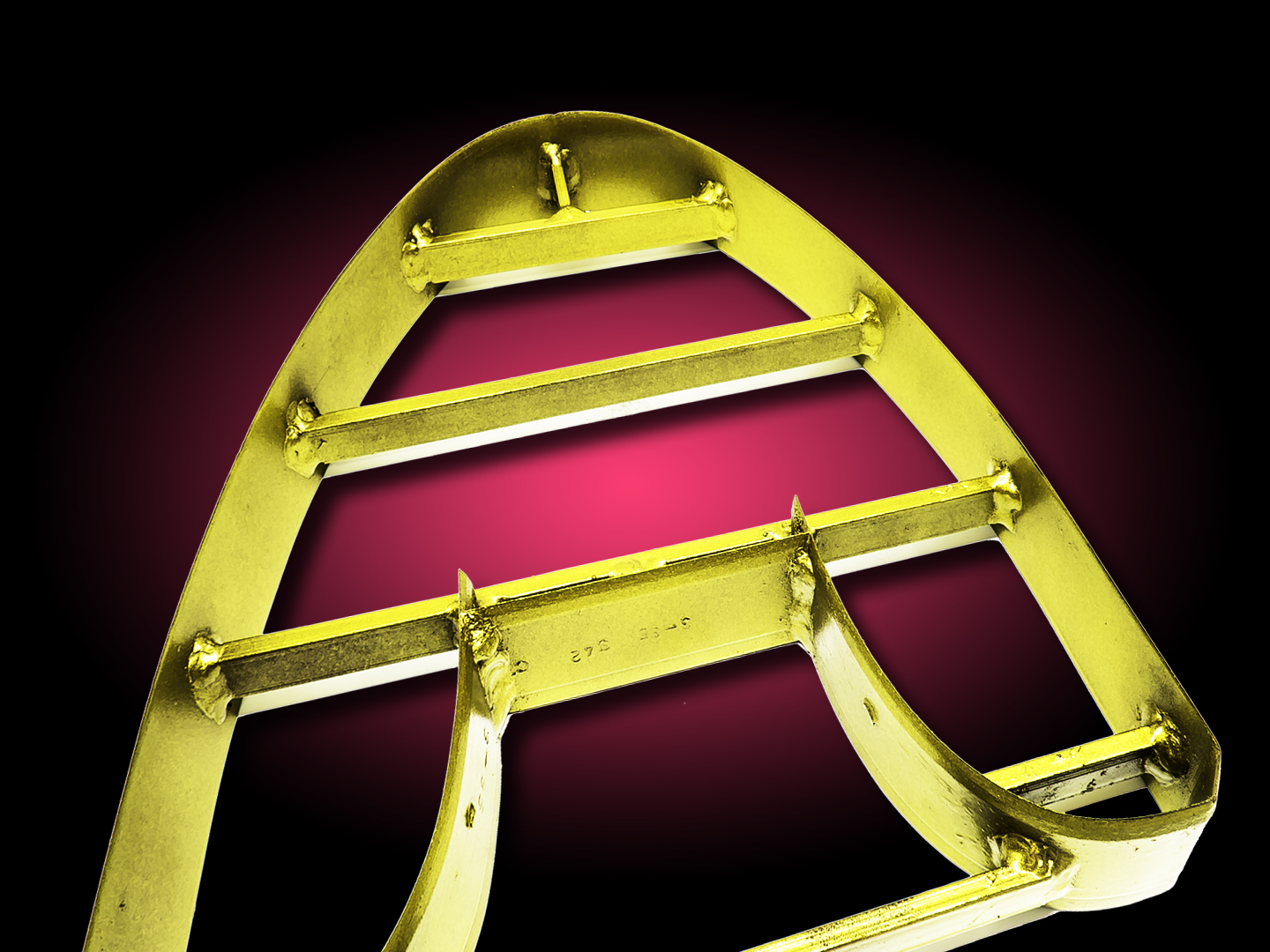

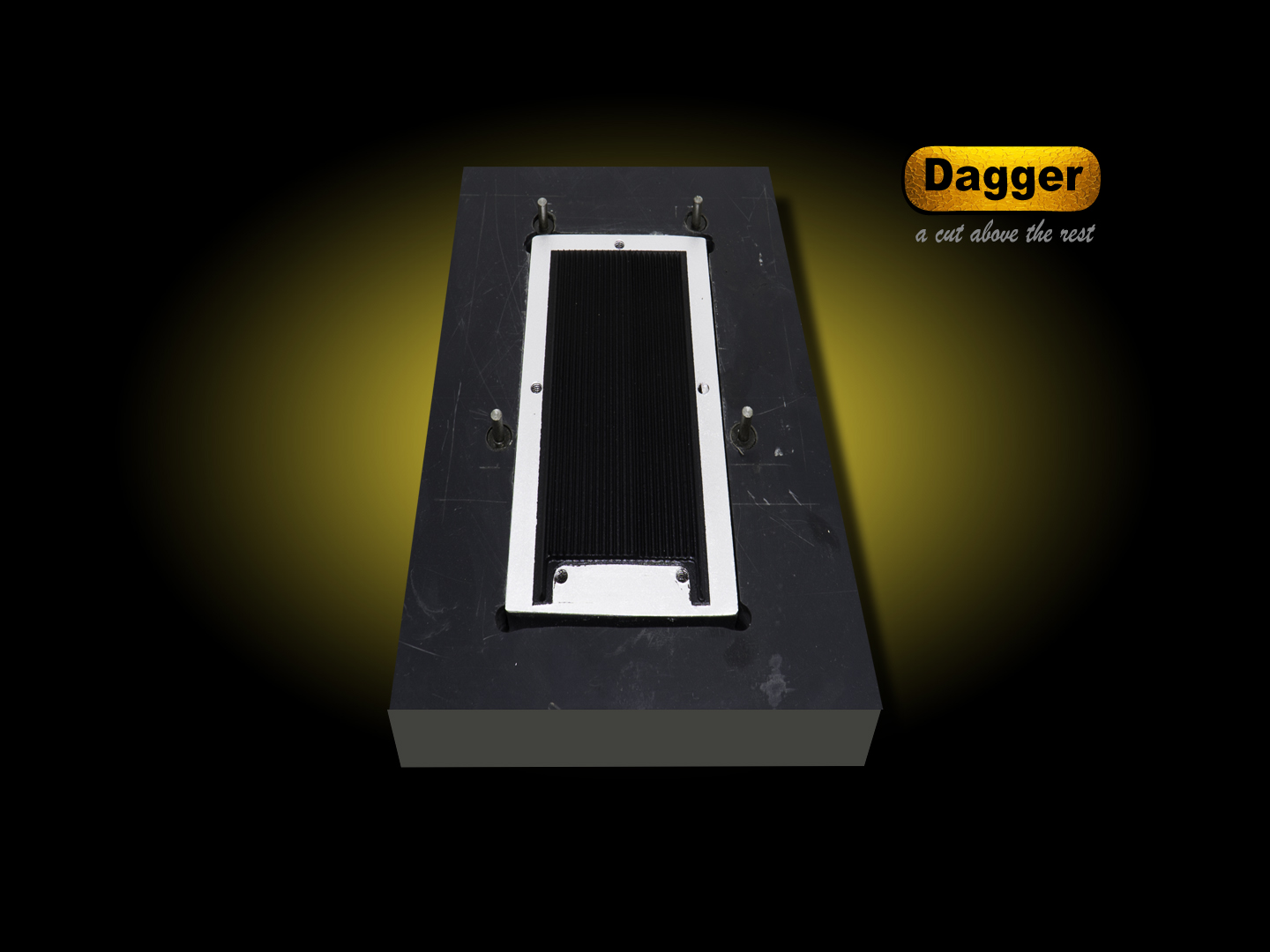

Sup through and Forged dies

Sup through or clearance dies are special dies that are for precise multilayer cutting with relief at other end...

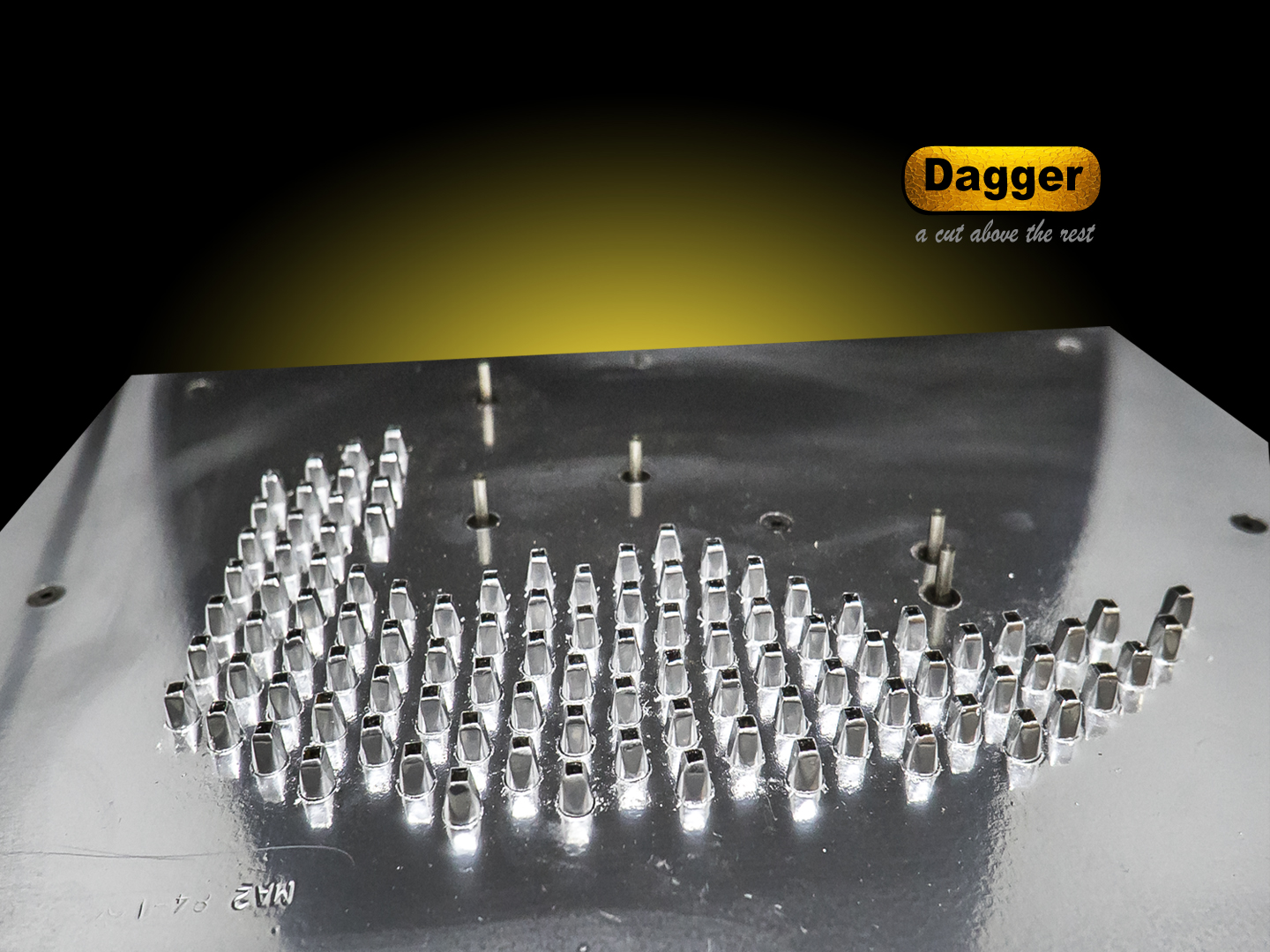

CNC milled and Hybrid Dies

A milled die is made out of solid block of mild steel. Small and intricate design can be achieved with high precision...

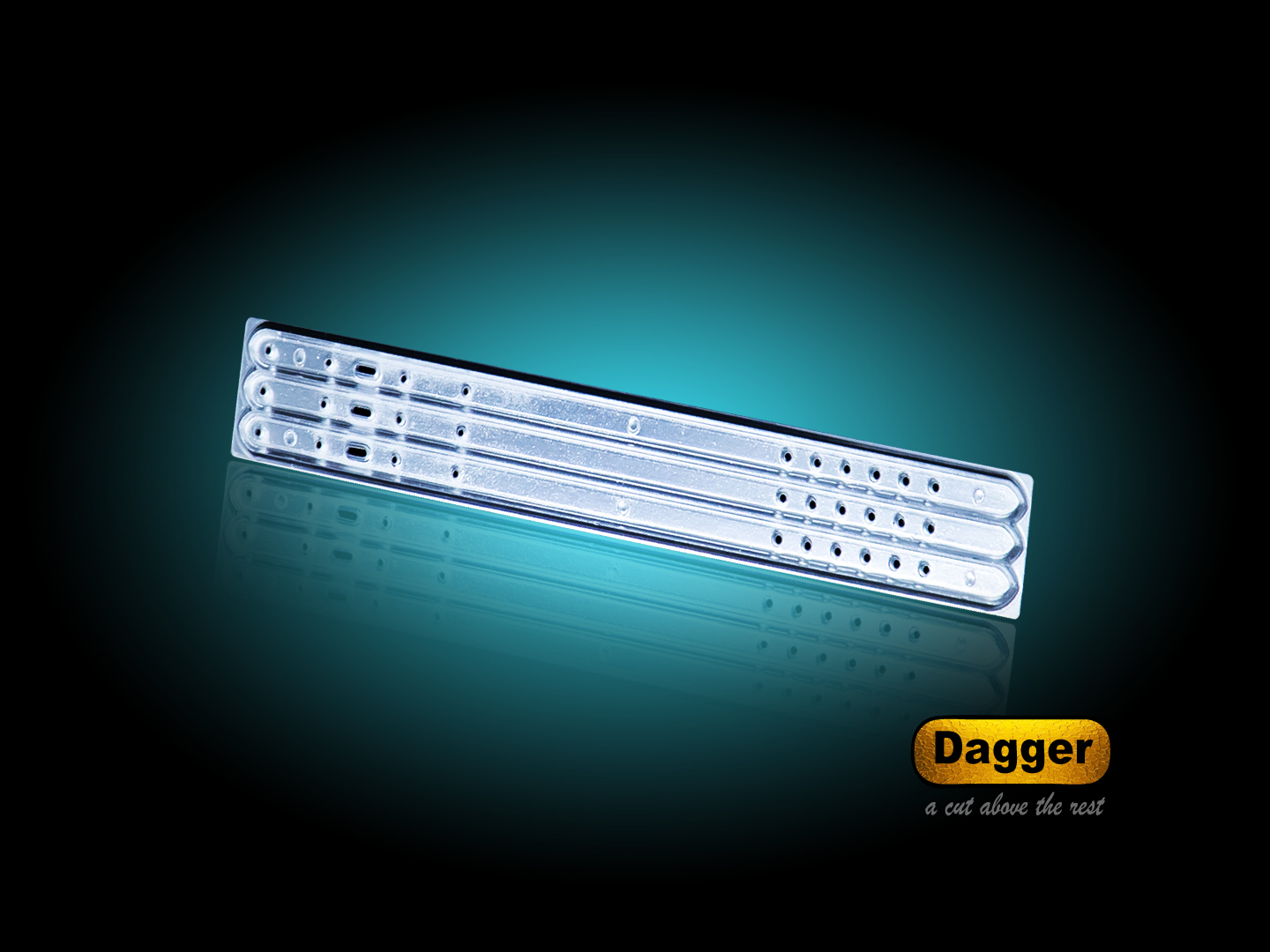

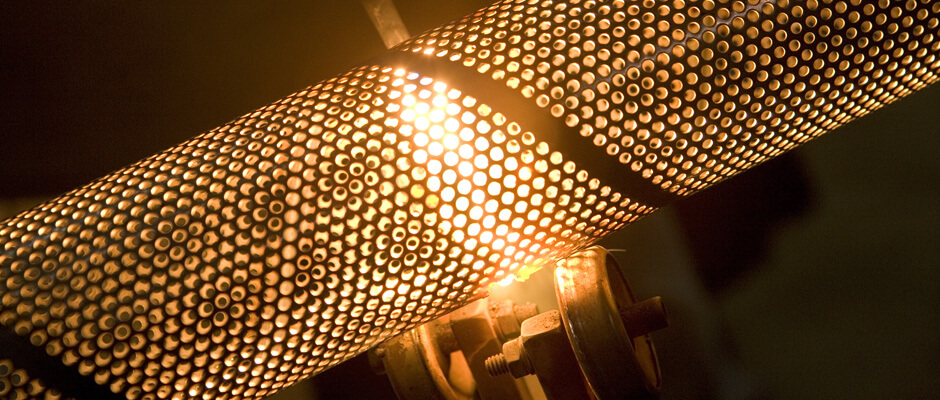

Perforating tubes and marking strips

Perforating tubes are hollow tubes with hole diameter ranges from 19 to 32mm...